One day while Mitch Payton and MXA’s Jody Weisel were reminiscing about the old days, Mitch said, “If you want to test our 2019 Supercross bike, just tell me the day.” You would have thought Jody would have said, “Great! How about tomorrow? Or later this afternoon?” but he didn’t.

The downfall of many multi-tools is that they can be fiddly to use and not give you much leverage from the short body.

Specifying threads that are longer than necessary can increase the cost of CNC parts, as special tooling may be required.

Still on the terminals, they also work with bare wires and banana plugs. The holes for banana plugs also reach a little into the cabinet, so even they stick out less than the usual amount. Finally, the nuts on the terminals have a larger diameter than usual. That makes it easier to do them up tightly.

1. I expect that DoD will, once again, change nothing about the 5.56mm ammo we currently use – except perhaps to go back from the copper M855A1 round to the (now) venerable M855, because it’s cheaper and more accurate. 2. That having been said, perhaps into the mix of suggested different calibers (I do like the Grendel for a 5.56mm replacement) we can add a change in bullets. Try a heavier match-grade bullet in 5.56mm: No need to change the firearms (though it WOULD perform better out of a 16 inch as opposed to a 14.5 inch barrel), and would be more useful at all ranges out to 500-600 meters than the 62 grain bullets, while still usable at CQB distances. I hand-load mine; was using the 69 grain Match King with Varget or H335 powder – but the recommended loads didn’t get muzzle v. greater than about 2600 fps. I tried similar Noslers, and their accuracy recommendation calls for A2230 powder (23.5 grains; max load) which moves that heavier bullet at almost 3k fps. For accuracy, I’ve achieved 1 MOA at 300 yards out of a 20 inch, 1:9 twist Bushmaster barrel. This was a three-inch group from a bench at 300 – the accuracy we needed in Afghanistan, and couldn’t get with issue ammo. My wife’s M&P-15 with 16 inch barrel (1:8 twist) gets almost the same: I was looking for both greater accuracy and greater “smack” and achieved both – though nothing’s perfect. (I’d like to try Grendel, but cost is currently prohibitive, especially to build ammo stocks.)

Manufacturers face strict health, safety and environmental (HSE) regulations due to the release of potentially harmful substances, such as NOx emissions in the air and nitrate effluents in water.

While I love the 300 blackout, its designed purpose was to replace submachine guns, increase modularity, reduce training, and improve logistics. It was not meant for a front line battle rifle, it is purpose driven. Meanwhile, the 6.8SPC is an ideal cartridge and a perfect performance envelope, but to effectively use it would require a new rifle built around the chambering itself. Not something a country twenty trillion dollars in debt can realistically look at.

Well it was true, because for all his introvertedness, he had a super-ego. Freddie Tavares would be working with him in the shop on a particular design—let’s say changes of one kind and another, upgrading. He’d tell Freddie to do something, and he’d go ahead and do it, and then he’d always have to bring it back for Leo’s inspection. Leo would take a look at it with that one eye, and sometimes he’d take a loupe out and look at it.

Properly bracing the seat-back is also very important. Kirkey makes a bracket that matches the contour of the seat and can be secured in several ways — the key being to use multiple fasteners and spread the load out as much as possible. Because of the proximity of T-Rex’s seat to the rollcage, some special tabs were made.

Figure 12. Nitrided layer, plated with aluminum foil. The porous layer inside the compound layer is well visible. Magnification 200x.

Specifying threads that are longer than necessary can increase the cost of CNC parts, as special tooling may be required.

For the preparation methods, the first step after sectioning is grinding the samples for one minute on the PlanarMet™ 300. The alumina wheel, with a grit size of 120 [P120] (Figure 2), and adjusted parameters such as 30 N per sample, head speed (base speed at 1500 rpm), and the relative rotation of head and base, dressing depth and dressing cycle, ensure continuous and steady material removal by saving on consumable costs. Based on the material hardness, the MRR is in the 250-800 µm/minute range, with an even scratch pattern.

Femail reveal the best Black Friday deals of 2017 | 201 202 304 D669 Related Video:

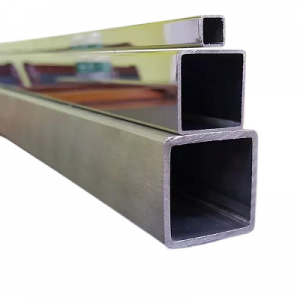

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for 2205 430 304 Steel Strips, 65mn Steel Strip, Pipe Fitting Names And Parts, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.