Welcome To MZ STEEL

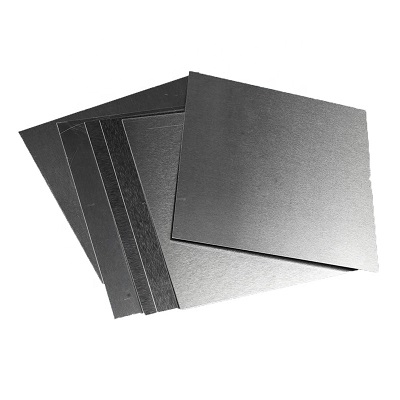

High Quality Hot Sale Nickel Alloy Sheet Incoloy 800 Plate

| Place of Origin: | Shanghai, China |

| Type: | Nickel Plate |

| Application: | Hydrocarbon cracking |

| Grade: | Incoloy 800/800h Uns N08810 |

| Ni (Min): | 38 |

| Powder Or Not: | Not Powder |

| Ultimate Strength (≥ MPa): | 1400 |

| Elongation (≥ %): | 22 |

| Model Number: | UNS N08 |

| Brand Name: | MZ Steel |

| Thickness: | 0.3-120mm |

| Width: | 1000mm/1219mm/1500mm |

| Shape: | Round.square.Rectangle |

| Sample: | Free sample |

| Surface: | 2B, NO.1 |

| Condition: | Annealed, Heat Treatment |

| Certificate: | EN 10204 Type 3.1 |

| Technique: | Hot Rolled, Cold Rolled |

| Stock: | In stock |

| key words: | Incoloy 800 nickel plate |

Inconel 800 800HT Nickel Alloy Sheet For Industrial Furnace

INCOLOY 800H / 800HT ASTM B409, B 408, B407, B564 UNS Number N08810/N08811

Other common names: Alloy 800, Alloy 800H, Inconel 800, Alloy 800HT

Incoloy 800, 800H, and 800HT are nickel-iron-chromium alloys with good strength and excellent resistance to oxidation and carburization in high-temperature exposure. These nickel steel alloys are identical except for the higher level of carbon in alloy 800H, and the addition of up to 1.20 percent aluminum and titanium in alloy 800HT. Incoloy 800 was the first of these alloys and it was slightly modified into Incoloy 800H. This modification was to control carbon (.05-.10%) and grain size to optimize stress rupture properties. Incoloy 800HT has further modifications to the combined titanium and aluminum levels (.85-1.20%) to ensure optimum high temperature properties. The nickel alloy is dual certified (800H/HT) and combines the properties of both forms. Incoloy 800H/HT alloy was intended for high temperature structural applications. The nickel content makes the alloys highly resistant to both chloride stress-corrosion cracking and to embrittlement from precipitation of sigma phase. The general corrosion resistance is excellent. In the solution annealed condition, alloys 800H and 800HT have superior creep and stress rupture properties. Today, most suppliers, including Mega Mex, only carry the dual certified 800H/HT alloy.

Incoloy 800 is primarily used in applications with temperatures up to 1100° F, where alloys 800H and 800HT are normally used in temperatures above 1100° F where resistance to creep and rupture is required. The chemical balance allows the nickel steel alloy to exhibit excellent resistance to carburization, oxidation and nitriding atmospheres. Incoloy 800HT will not become embrittled even after long periods of usage in the 1200-1600° F range where many stainless steels become brittle. Excellent cold forming characteristics typically associated with the nickel-chromium alloys are exhibited with 800HT. When cold formed extensively the grain size produces a visibly undulated surface called “orange peel”. Incoloy 800HT can be welded by the common techniques used on stainless steels.

What are the characteristics of Incoloy 800H/HT?

- High temperature strength

- High creep rupture strength

- Resistant to oxidation and carburization in high temperature environments

- Good corrosion resistance in many acidic environments

- Good resistance to many sulfur-containing atmospheres

In what applications is Incoloy 800H/HT used?

- Ethylene furnace quench boilers

- Hydrocarbon cracking

- Valves, fittings and other components exposed to corrosive attack from 1100-1800° F

- Industrial furnaces

- Heat-treating equipment

- Chemical and petrochemical processing

- Super-heater and re-heaters in power plants

- Pressure vessels

- Heat exchangers

Chemical Composition:

Alloy 800 (UNS N08800) Chemical Composition, %

| Ni | Cr | Fe | C | Al | Ti | Al+Ti |

| 30-35 | 19-23 | 39.5min | 0.1max | 0.15-0.6 | 0.15-0.6 | 0.3-1.2 |

Alloy 800H (UNS N08810) Chemical Composition, %

| Ni | Cr | Fe | C | Al | Ti | Al+Ti |

| 30-35 | 19-23 | 39.5min | 0.05-0.1 | 0.15-0.6 | 0.15-0.6 | 0.3-1.2 |

Alloy 800HT (UNS N08811) Chemical Composition, %

| Ni | Cr | Fe | C | Al | Ti | Al+Ti |

| 30-35 | 19-23 | 39.5min | 0.06-0.1 | 0.25-0.6 | 0.25-0.6 | 0.85-1.2 |

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..