Welcome To MZ STEEL

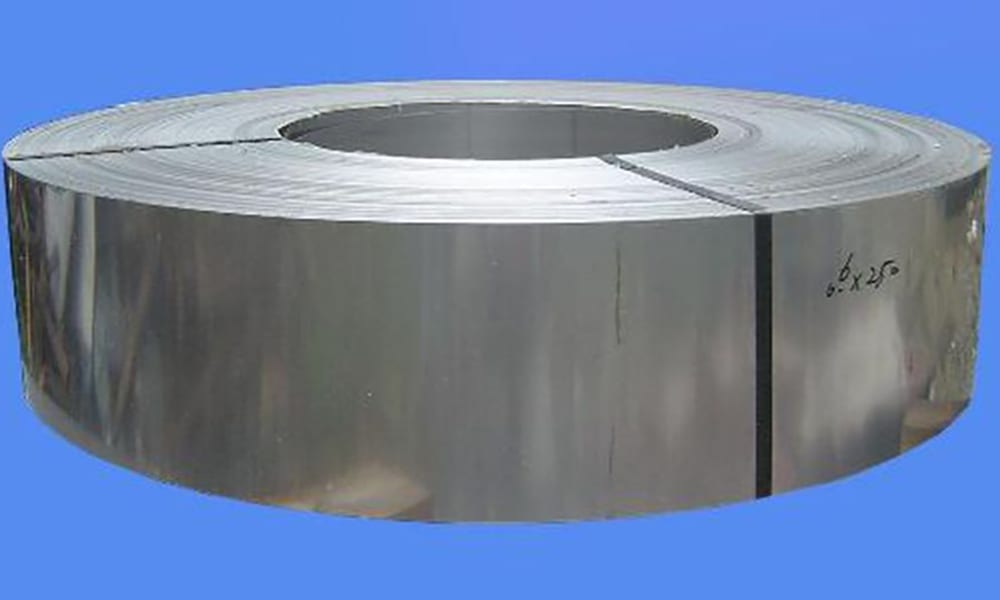

China Gold Supplier for Aisi 304 Stainless Steel Tube - Cold Rolled Stainless Steel Coils Embossing Aisi 304 With Polishing Punch Boards – Mizhang

China Gold Supplier for Aisi 304 Stainless Steel Tube - Cold Rolled Stainless Steel Coils Embossing Aisi 304 With Polishing Punch Boards – Mizhang Detail:

Product Detail:

Tisco / Baosteel / Lisco Hot Rolled 316 / 316 Stainless Steel Coil With 1000 / 1219 / 1500 Width.

Quick Detail:

| Name | Stainless steel coil | Brand Name | SX |

| Color | natural color | Feature | High quality |

| Grade | 200,300,400 series | Certificate | SGS,ISO,BV,CE |

Description:

1. Brand: ISCO, LISCO, TISCO

2. Commodity: Stainless steel coil

3. Grade: 304,304L,321,321H,316,316L,317L,310S

4. Certification: ISO

5. Surface: 2B, BA, NO.4, NO.2 or as requested

6. thickness: 0.3-100mm

7. width: 50-2000mm

8. Length: 1000mm-11000mm or as customer’s requirement

9. Standard: JIS, AISI, ASTM, GB, DIN, etc.

10.Delivery time: Within 15 days since get the deposit

11.MOQ:10 tons

12.Package: Standard sea-worthy packaging covered with PVC , or as buyers’ requirement

Applications:

|

Applications: |

medical |

| food processing | |

| chemical processing | |

| high vacuum | |

| wastewater treatment | |

| power generation | |

| pharmaceutical | |

| paper and pulp | |

| heat treatment industries and more |

Specifications:

|

Thickness |

0.3mm-100mm |

|

Width |

1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm |

|

Length |

2000mm-6000mmor as customer request |

|

Standard |

ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

|

Material |

201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 430, etc |

|

Surface |

2B, BA, 8K, No. 4 No.1 |

|

Mill: |

TISCO, LISCO, BAO STEEL |

|

Packaging |

Standard export sea-worthy packing |

|

Technique |

Hot rolled / cold rolled |

|

Delivery time |

10-25days |

|

Supply ability |

700 metric tons/ month |

|

Payment terms |

L/C, T/T |

|

Application range |

Foodstuff, gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy Medical equipment, fertilizer, etc. |

|

Note |

We can produce other standard as the customers’ requirement |

| C | Si | Mn | P | S | Ni | Cr | Cu |

| 201 half Cu | 0.15Max | 1.0Max | 7.5-10.0 | 0.06Max | 0.03Max | 0.5-0.7 | 14.0-16.0 |

| J4 | 0.10Max | 1.0Max | 7.5-10.0 | 0.06Max | 0.03Max | 0.8-1.0 | 14.0-16.0 |

| 201 | 0.10Max | 1.0Max | 7.5-10.0 | 0.06Max | 0.03Max | 1.0 | 16.0-18.0 |

| 202 | 0.15Max | 1.0Max | 7.5-10.0 | 0.06Max | 0.03Max | 4.0 | 17.0-19.0 |

| 301 | 0.15Max | 1.0Max | 2.0Max | 0.065Max | 0.03Max | 6.0 | 16.0-18.0 |

| 304 | 0.07Max | 1.0Max | 2.0Max | 0.035Max | 0.03Max | 8.0 | 17.0-19.0 |

| 304L | 0.03Max | 1.0Max | 2.0Max | 0.035Max | 0.03Max | 8.0 | 18.0-20.0 |

| 316 | 0.08Max | 1.0Max | 2.0Max | 0.035Max | 0.03Max | 10.0 | 16.0-18.0 |

| 316L | 0.03Max | 1.0Max | 2.0Max | 0.035Max | 0.03Max | 10.0 | 16.0-18.0 |

| 321 | 0.12Max | 1.0Max | 2.0Max | 0.035Max | 0.03Max | 9.0 | 17.0-19.0 |

| 309S | 0.08Max | 1.0Max | 2.0Max | 0.035Max | 0.03Max | 12.0 | 22.0-24.0 |

| 310S | 0.08Max | 1.0Max | 2.0Max | 0.035Max | 0.03Max | 19.0 | 24.0-26.0 |

| 410 | 0.15Max | 1.0Max | 1.0Max | 0.035Max | 0.03Max | 0.06Max | 11.5-13.5 |

| 410S | 0.08Max | 1.0Max | 1.0Max | 0.035Max | 0.03Max | 0.06Max | 11.5-13.5 |

| 409 | 0.08Max | 1.0Max | 1.0Max | 0.040Max | 0.03Max | 0.06Max | 10.5-11.5 |

| 409L | 0.03Max | 1.0Max | 1.0Max | 0.040Max | 0.03Max | 0.06Max | 10.5-11.5 |

| 420J2 | 0.35Max | 1.0Max | 1.0Max | 0.040Max | 0.03Max | 0.06Max | 12.0-14.0 |

| 430 | 0.12Max | 0.7Max | 1.0Max | 0.040Max | 0.03Max | 0.06Max | 16.0-18.0 |

| Surface | Definition | Application |

| 2B | Those finished, after cold rolling,by heat treatment,picklingor other equivalenttreatment and lastly by

cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils,Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive

of suitable grain size. |

Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there

to after hot rolling. |

Chemical tank, pipe |

Competitive Advantage:

• Country of Origin

• Experienced Staff

• Professional services

• Packaging

• Best Price

• Prompt Delivery

Product detail pictures:

Related Product Guide:

Worldwide Comprehensive Review of Builder Hardware Market Trends and Its Development | 8mm Precision Steel Rod

Oval Gear Flowmeter Market : Comprehensive Study Explores Huge Growth in Future | Leading Key Players ALIA GROUP INC, Badger Meter, Kytola Instruments Oy, Numak srl, PIUSI S.p.A., Riels Instruments, SIKA, Sotera, Bopp & Reuther Messtechnik GmbH, and more. | 0.8mm Stainless Steel Sheet

We also offer product sourcing and flight consolidation services. We have our own factory and sourcing office. We can provide you with almost every type of product related to our product range for China Gold Supplier for Aisi 304 Stainless Steel Tube - Cold Rolled Stainless Steel Coils Embossing Aisi 304 With Polishing Punch Boards – Mizhang , The product will supply to all over the world, such as: Casablanca, Norwegian, Chile, We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

This company conforms to the market requirement and joins in the market competition by its high quality product, this is an enterprise that have Chinese spirit.

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..